We are Supplier, Services Provider of Computerised Fully Automatic Brinell Hardness Testers and our set up is in Pune, Maharashtra, India

Computerised Fully Automatic Brinell Hardness Tester, Model B3000 - PC - FA is fabricated from steel plates and is designed for precise loading system. It is fully automatic machine for production testing. Once the job is placed on testing table and press "Cycle Start" button. The job is raised and brought in contact with clamping device. Then identor is swivelled and brought in vertical loading position. The loading operation starts. After preset dwelling timer, unloading operation starts. As soon as load is fully removed, the indentor is swivelled and the image is digitalized using a CCD camera fitted on machine and captured by the PC.The diameter of indentation is measured by PC and the Brinell Hardness is displayed on monitor with the help of "State of Art" technology software. The job is lowered down and here the auto cycle is over.

Operationally the machine can be operated after a lapse of interval without operation of push button, so that operator has only to do loading and unloading of job on machine.

This tester is designed for measuring hardness of metallic parts with wide testing range from soft to hard and its accurate results are widely acclaimed.

This tester conforms to IS:2281, BS:10003 and ASTME - 10.

- Fully automatic machine for production testing.

- Fully computerised (PC based) Brinell Hardness Tester.

- Direct and accurate measurement of Brinell hardness number using "State of Art" image processing technology.

- Wide testing range : From soft metal such as lead up to hardest, like tempered steel.

- High accuracy and repeatability of measurement at all loads.

- Advanced Windowbased software:

*PC & Printer is not in our standard scope of supply.

Latest GUI features :

- Latest GUI features with user friendly software.

- Online indentation setting and focusing on PC monitor.

- Advanced image processing : Algorithms implemented for precise calculations of hardness numbers with various options to cover all ranges of specimens.

- Batch file processing : Option for data/storage and reports generation.

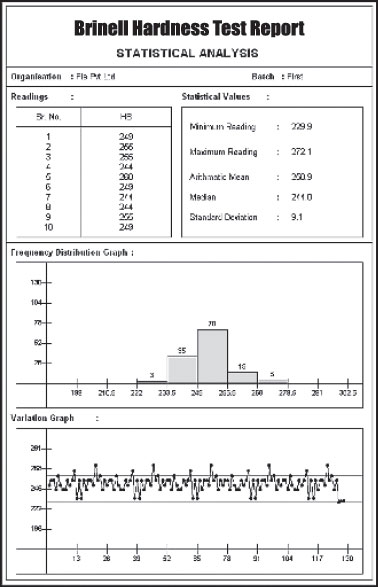

- Statical Evaluation : Software for calculating standard deviation, mean, medium, frequency distribution graph, variation graph etc.

- Calibration mode facility.

- Extendibility for future advanced image processing analysis, requirements.

- "Auto measurement start" from machine.

Scope of Supply :

- Basic machine with CCD camera, optics with illumination system and connecting cable.

- USB device for Video.

- PC and Windows operating system is to be procured by customer.

Customized Brinell hardness Testers

Application :

Computerized Brinell Hardness Tester, Model: B3000-PC-FA is fabricated from steel plate sand is designed for

precise loading system.

It is fully automatic machine for production testing.

Ones the job is placed on testing table and press "Cycle start" button the job is raised and brought in contact

with clamping device.

Then loading operation starts.

After preset dwelling timer, unloading operation starts. As soon as load is fully

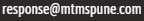

removed, the indenter is swiveled and the image is digitalized using a CCD camera fitted on machine and

captured by the PC.

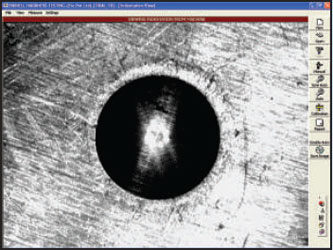

The diameter of indentation is measured by PC and the Brinell hardness is displayed on monitor with help of

"state of the art" technology software.

The job is lowered down and here the auto cycle is over.

Operationally the machine can be operated after lapse of interval without operation of push button, so that

operator has only to do loading and unloading of job on machine.

This tester is designed for measuring hardness of metallic parts with wide testing range from soft to hard and its

accurate results are widely acclaimed.

This tester confirms to IS: 1500-2.

Indentation View

Indentation View Result View

Result View| Test Loads | kgf | 250 to 3000 instages of 250 kgf. |

| Magnification of objectives |

- | 4X |

| Maximum Test Height | mm | 380 |

| Scale least count | mm | 0.01 |

| Throat Depth | mm | 200 |

| Weight (Approx.) | mm | 450 |

| Power Supply | V/Cy/Ph | 415/50/3 |

| Measurement Range | mm | 1-6 |

| Testing Table 200 mmdia. | 1No. |

| Testing Table 70 mm dia. With V groove for round jobs 10 to 80mm dia. | 1No. |

| Ball holder 5mm | 1No. |

| Ball holder 10mm | 1No. |

| Test BlockHB-5/750 | 1No. |

| Test BlockHB-10/3000 | 1No. |

| Allen Spanner | 4Nos. |

| Telescopic cover for elevating screw protection. | 1Set |

| Electric Cord | 1No. |

| USB device for Video | 1No. |

| Instruction Manual | 1Book |