Digital Rockwell Hardness Testing Machines Series : RASNE-3

We are Supplier, Services Provider of Hardness Testing Machines Series - RASNE and our set up is in Pune, Maharashtra, India

RASNE-3

RASNET-3

RASNEB-3

Features :

- This is motorized machine having automatic loading / unloading cycle suitable for production testing.

- The machine body is having a taper front look and large size read-out in the front. The machine is powder coated for better look. The paint shade do not fade and machine looks like new over years.

- The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accuracy is retained for years together due to hardenedbush.

- A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy.

- An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enables testing of small dia. Pin or ball upto 3 mm dia.

- These models are provided with automatic working cycle and digital LCD display with 0.1 Rockwell resolution. This insures productivity with better accuracy.

- IS: 1586 (Part2) 2012 for Rockwell and Rockwell superficial test.

- IS: 1500 (Part2) 2013 for Brinell hardness test.

Principle :

Rockwell, Rockwell superficial & Rockwell cum Brinell test consists of forcing an indentor (Diamond or Ball)in to the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. RASNE series machines are suitable for Rockwell, Rockwell superficial & Rockwell cum Brinell tests. These are motorized digital Hardness testers having LCD display for easy hardness measurement. The results are displayed in 0.1 Rockwell unit for more accurate measurement.

Operation :

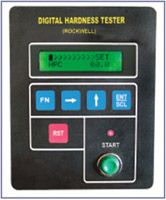

Various parameters of test can be set on front panel by operation of key board and observing LCD display Viz high/low limits, dwell time, auto / manual start, printer selection, scale selection etc. All set data can be verified edited by pressing SCL key one after another. Machine operation is very simple. The normal mode is a bar followed by "SET" indication. Raise elevating screw slowly through bar indication till "SET" position which will show "PRESSSTART" indication.

Now press "START" button. Loading / unloading cycle will be completed and hardness is shown on LCD display with high/Good/Low indication. Lower down elevating screw. Panel will show normal mode for next test. Also when required 'AUTO START' set 'AUTO START' on front panel by operation of key board & observing LCD Display then raise elevating screw slowly through bar indication till "SET" position then it will starts loading/unloading cycle automatically & hardness is shown on LCDD is play with High / Good / Low indication.

Rockwell, Rockwell superficial & Rockwell cum Brinell test consists of forcing an indentor (Diamond or Ball)in to the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value. RASNE series machines are suitable for Rockwell, Rockwell superficial & Rockwell cum Brinell tests. These are motorized digital Hardness testers having LCD display for easy hardness measurement. The results are displayed in 0.1 Rockwell unit for more accurate measurement.

Operation :

Various parameters of test can be set on front panel by operation of key board and observing LCD display Viz high/low limits, dwell time, auto / manual start, printer selection, scale selection etc. All set data can be verified edited by pressing SCL key one after another. Machine operation is very simple. The normal mode is a bar followed by "SET" indication. Raise elevating screw slowly through bar indication till "SET" position which will show "PRESSSTART" indication.

Now press "START" button. Loading / unloading cycle will be completed and hardness is shown on LCD display with high/Good/Low indication. Lower down elevating screw. Panel will show normal mode for next test. Also when required 'AUTO START' set 'AUTO START' on front panel by operation of key board & observing LCD Display then raise elevating screw slowly through bar indication till "SET" position then it will starts loading/unloading cycle automatically & hardness is shown on LCDD is play with High / Good / Low indication.

Standard Accessories :

Model |

RASNE-3 |

RASNET-3 |

RASNEB-3 |

Testing Table 50mm dia. |

1 |

1 |

1 |

Testing Table 38mm dia. with 'V' groove for round jobs 6-45 mm dia. |

1 |

1 |

1 |

Diamond indentor - Rockwell RA |

1 |

- |

1 |

Diamond indentor - Rockwell SF |

- |

1 |

- |

Steel Ball Indentor 1/16" with 5 spare balls |

1 |

1 |

1 |

Steel Ball Indentor 2.5 mm with 5 spare balls |

- |

- |

1 |

Test Block Rockwell "C" |

1 |

1 |

1 |

Test Block Rockwell "B" |

1 |

1 |

1 |

Test Block HB 2.5 / 187.5 |

- |

- |

1 |

Test Block HR 30 N |

- |

1 |

- |

Allen Spanners |

5 |

5 |

5 |

Screw Driver |

1 |

1 |

1 |

Clamping Device |

1 |

1 |

1 |

Wooden Box for Std. Accessories |

1 |

1 |

1 |

Telescopic Sleeves for Elevating screw position |

1 Set |

1 Set |

1 Set |

Spare Fuse 1 Amp. |

1 |

1 |

1 |

Technical Specifications:

Model |

Unit |

RASNE-3 |

RASNET-3 |

RASNEB-3 |

Major Load |

N (kgf) |

588.4, 980.7, 1471 (60, 100, 150) |

147.1, 294.2, 441.3, 588.4, 980.7, 1471 (15, 30, 45, 60, 100, 150) |

588.4, 980.7, 1471, 1839, 2452 (60, 100, 150, 187.5, 250) |

Minor Load |

N (kgf) |

98.07 (10) |

29.42, 98.07 (3, 10) |

98.07 (10) |

Max.Test height |

mm |

230 |

230 |

230 |

Depth of throat |

mm |

133 |

133 |

133 |

Net wt. Approx. |

kg. |

75 |

77 |

77 |

M/c Dimensions |

mm |

L-450, W-175, H-627 |

L-450, W-175, H-627 |

L-450, W-175, H-627 |

Motorized Digital Hardness Tester :

Model |

RASNE-3 |

RASNET-3 |

RASNEB-3 |

Type |

Digital Rockwell |

Digital Rockwell & Rockwell Superficial |

Digital Rockwell cum Brinell |

Operation Cycle |

Automatic

Load / Dwell / Unload |

Automatic

Load / Dwell / Unload |

Automatic

Load / Dwell / Unload |

Preliminary Test Force |

98.07 N (10 kgf) |

29.42N (3kgf) & 98.07N (10kgf) |

98.07 N (10kgf) |

Additional Test Force |

490.3, 882.6, 1373 N (50, 90, 140 kgf) |

117.7, 264.8, 411.9, 490.3, 882.6, 1373 N (12, 27, 42, 50, 90, 140 kgf) |

490.3, 882.6, 1373, 1471, 2354N (50, 90, 140, 177.5, 240 kgf) |

Total Test Force |

588.4, 980.7, 1471 N (60, 100, 150 kgf) |

141.7, 294.2, 441.3, 588.4, 980.7, 1471N (15, 30, 45, 60, 100, 150 kgf) |

5800.4, 980.7, 1471, 1839, 2452N (60, 100, 150, 187.5, 250 kgf) |

Test Force Selection |

By external dialing |

By external dialing |

By external dialing |

Set Position |

With LCD bar indicator |

With LCD bar indicator |

With LCD bar indicator |

Key Board Entry |

Through membrane switches for scale, GO-No GO & dwell time selection |

Through membrane switches for scale, GO-ON GO & dwell time selection |

Through membrane switches for scale, GO-ON GO dwell time selection |

Resolution |

0.1 Rockwell |

0.1 Rockwell or 0.1 Rockwell Superficial |

0.1 Rockwell |

Output |

Parallel output for connecting Dot Matrix Printer to get results indicating serial no. of tests, hardness scale, hardness value & high/good/low indication |

Parallel output for connecting Dot Matrix Printer to get results indicating serial no. of tests, hardness scale, hardness value & high / good / low indication |

Parallel output for connecting Dot Matrix Printer to get results indicating serial no. of tests, hardness scale, hardness value & high/good/low indication |

Optional |

Serial PD interface & windows software |

Serial PC interface & windows software |

Serial PC Interface & windows software for only Rockwell scales |

Note : For Brinell scale - manually select (187.5 or 250 kgf) with respected ball indentor. At that time take reference of set point only. Apply the load, then measure the impression dia by Brinell microscope only. (No Brinell scale display on screen).

Optional Accessories :

- Steel ball indentor 1/8", 1/4", 1/2".

- Testing Table 20mm dia.

- Testing Table 70mm dia. with 'V' groove for round jobs 10 to 80mm dia.

- Vari-rest to support add shaped jobs.

- Jominy test fixture for end quench test.

- Gooseneck Adoptor No.1.

- Special diamond indentor suitable for Gooseneck Adoptor No.1.

- Short nib diamond indentor suitable for Goodseneck Adoptor No.1.

- Gooseneck Adoptor No.2.

- Special diamond indentor suitable for Goodseneck Adoptor No.2.

- Gooseneck Adoptor No.3.

- Raised center testing table 15mm dia.

- Diamond Spot Anvil.

- Cylindron anvil for testing big jobs above 20mm dia.

- Eyeball anvil with 25.4mm dia. or 38mm dia. ball.

- Gooseneck anvil for pipes 5 to 25mm ID with 5mm step inserts.

- Jack rest for long and heavy jobs.