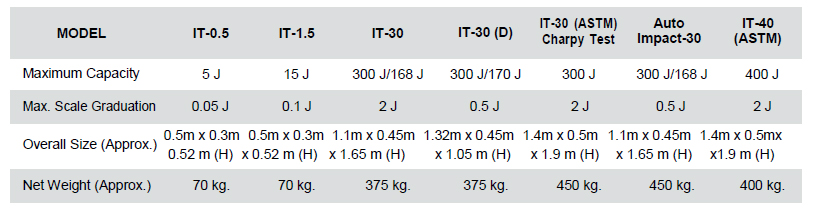

We are Supplier, Services Provider of Impact Testing Machines and our set up is in Pune, Maharashtra, India

The pendulum Impact Tester, Model IT-30 is

designed for conducting Izod, Charpy test. The test methods confirm to BS: 131: PART 4-1972

(Amended 15 Aug. 1993) BSEN: 10045 - 2:1993.

The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy the lower one for Izod testing. On release, the pendulum swings down to break the specimen & the energy absorbed in doing so is measured as the difference between the height of drop before rupture of the test specimen and is read from the maximum pointer position on the dial scale.

(It is read on digital readout in case of electronic machines.)

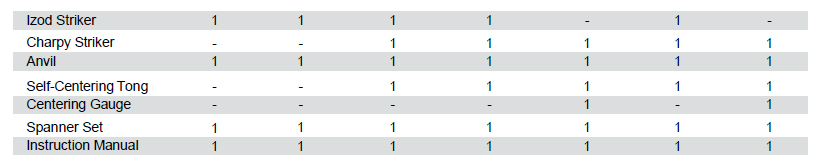

There are two strikers and one combined support anvil available for fitting in to the pendulum and on the base of machine for the Izod, Charpy test respectively. Changing from one striker to another is achieved simply by fixing the new striker into it’s position.

Model: IT-30

The Charpy test piece rests on alloy steel support anvils, fitted on the base of the machine rigidly held in

position by Allen screws. End stopper is provided for quickly and accurately locating the test piece centrally between the supports.

Izod Test :

The Izod Test piece is clamped vertically in Izod support fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size.

The front clamp piece and the Allen screw enable clamping of the test piece in correct height with the help of Izod setting gauge supplied

Model: IT - ASTM

The Impact Tester offered with 300 & 400 J energy exclusively for Charpy test confirming to ASTM E-

23. This machine is geometrically checked in the works to the more stringent requirements of the American standard. The accuracy of the machine is then verified by PROOF TEST by testing standard test specimens supplied by the NIST, USA. Two sets (Low & high energy-1 Set (4 Nos.) each.) must agree with the normal values within certain tolerance specified.

General Description:

The pendulum Impact Tester, Model: Auto Impact-30 is designed for conducting Izod, Charpy test. The test method confirm to BS: 131: PART 4-1972 (Amended 15 Aug. 1993) BSEN: 10045-2: 1993. In Auto Impact Tester, pendulum will lift, specimen will get loaded and pendulum will release automatically. Once specimen breaks, result will display on digital panel, and auto brakes will apply immediately. The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy and the lower one for Izod testing.

On auto release, the pendulum swing down to break the specimen and the energy absorbed in doing so is measured as the difference between the height of drop before rupture and height of rise after rupture of the test specimen and is read on digital panel in Joules.

Charpy Test:

The Charpy test piece rests on support anvils, fitted on the base of the machine rigidly held in position by Allen screws. End stopper is provided for quickly and accurately locating the

test piece centrally between the supports.

Izod Test:

The Izod Test piece is clamped vertically in Izod locating groove fitted on the base of the machine. The support is provided with a machined vertical groove to suit the test piece size. The front clamp piece and the Allen screw enable clamping of the

test piece in correct height with the help of Izod setting gauge

supplied.

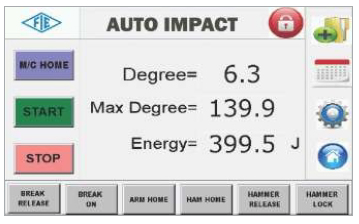

Home Screen

In Auto Impact-30, Pendulum will lift, specimen will get loaded and pendulum will release automatically. Once specimen breaks, result will display on digital panel, and auto brakes will apply immediately.

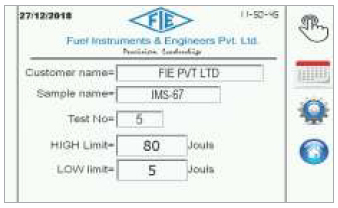

Data Entry

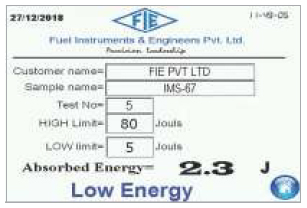

Result

USB Communication

General Description:

FIE's Charpy pendulum Impact Testing Machine, Model: IT-40 (ASTM) serves for conducting Charpy

impact testing according to ASTM-E23 standard to determine the behaviors of the metal especially of steel casting under impact stresses.

Features:

Fully automatic machine easy to operate. For safety machine cover with enclosure which are

having door interlocks so operator can works safely. High resolution encoder is fitted in machine which can read the absorbed energy less than 1J.

GUI Features:

Touch screen HMI.

USB output data logging. Thermal printer output.

Manual operation via touch screen. Calibration features.

New file creation.

Optional Accessories :

- Caliper gauge for checking V notch for Izod & Charpy.

- Templates for checking 10 x 10 mm cross section of Izod / Charpy test specimen.

- Depth notch gauge including V & U notch gauges for checking depth below V/U notch, angle and radius.

- Izod support for 0.450" dia Izod round specimen.

- Self-centering tong for quick and accurate setting of Charpy test specimen.

- 'V' notch milling cutter.

- 'U' notch milling cutter.

- Guards & Covers (For IT-30 D, Auto Impact-30, Auto Impact-40).