RAS

RAB - 250

RAB - TWIN

Rockwell Hardness Testers - RASN

Rockwell Hardness Testers - RASN-B

Rockwell Hardness Testers - RASNT

Rockwell Hardness Testers - RASNM

Rockwell Hardness Testers - RASNE

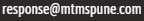

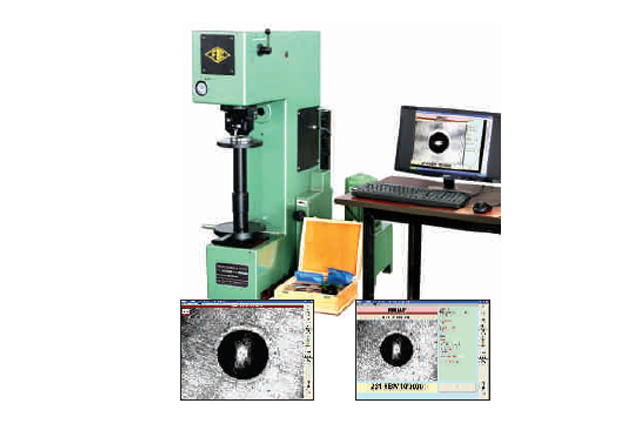

Fully Automatic Computerized Brinell Hardness Testing Machines - B 3000-PCFA

Digital Rockwell Hardness Tester RASNE-TFTKBD

Digital Touch Screen Rockwell Hardness Tester RASNE-TS

Fully Automatic Touch Screen Rockwell Hardness Tester RASN-TSFA

Optical Vickers Hardness Tester - VM 50

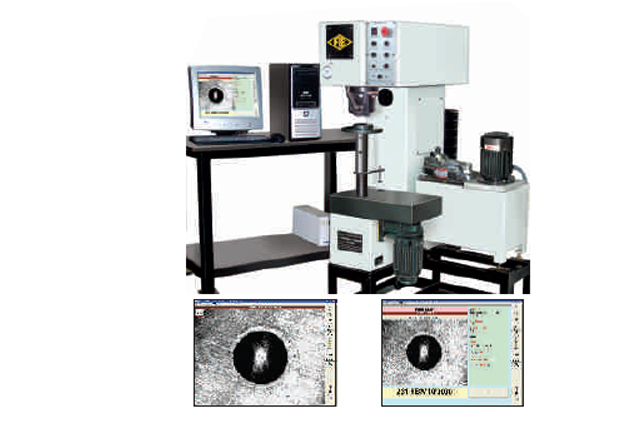

Computerized Vickers Hardness Tester - VM 50-PC

Computerized Touch Screen Vickers Hardness Tester - VM 50-TS

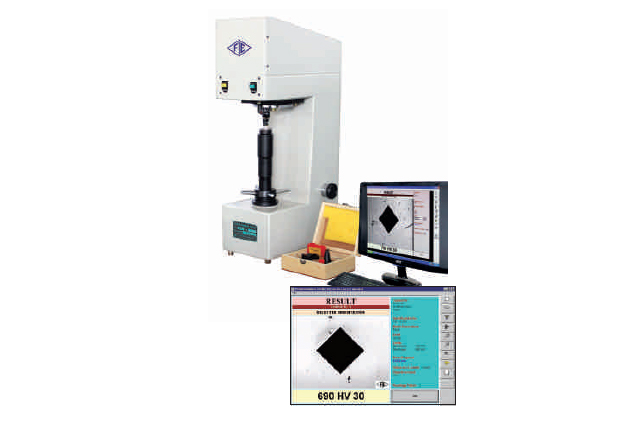

Computerized Micro-Vickers Hardness Tester - MV1-PC

Computerized Brinell Hardness Testers - B 3000-PC

Touch Screen Computerized Brinell Hardness Testers - B 3000-TS

Features :

We are Supplier, Services Provider of >Rockwell Hardness Testers and our set up is in Pune, Maharashtra, India

Rockwell, Rockwell Brinell Combined, Rockwell / Rockwell Superficial Combined System Hardness Testers. Hardness Testers, Model RAS, RAB-1, RAB-250, TWIN are manually operated. All these models are suitable for testing hardness of metals sand alloys of all kinds hard or soft, whether flat, round, or irregular shape. These testers are simple in design and easy to operate, yet sensitive & accurate. Various models from the wide range are suitable for schools, laboratories, tool-rooms, inspection, heat treatment departments, factories etc. These testers strictly confirms to IS : 1586 - 2000, ASTM : E 18 for Rockwell Superficial Test and IS : 2281 - 2005, ASTM : E 10 for Brinell test.| Model RAS : | Model RAB-1 | Model TWIN |

Automatic load selection with automatic zero setting dial gauge. Manual operation. |

Automatic load selection & automatic zero setting dial gauge. Facility for Brinell tests with 187.5 kgf. load with 2.5 mm Ball indicator, additional load 250 kgf. with 5mm Ball indentor for testing hardness of non- ferrous metals. |

Automatic load selection with automatic zero setting dial gauge. Manual operation. Diamond holder is guided in a ball cage, which enables testing of small pins having dia. Less than 6 mm (up to 3mm dia.) |

| Model RAB 250 | ||

Similar to 'RAB-1' but of bigger capacity. Diamond holder is guided in a ball cage, which enables testing of small pins having dia less than 6 mm ( up to 3 mm dia.) |

||

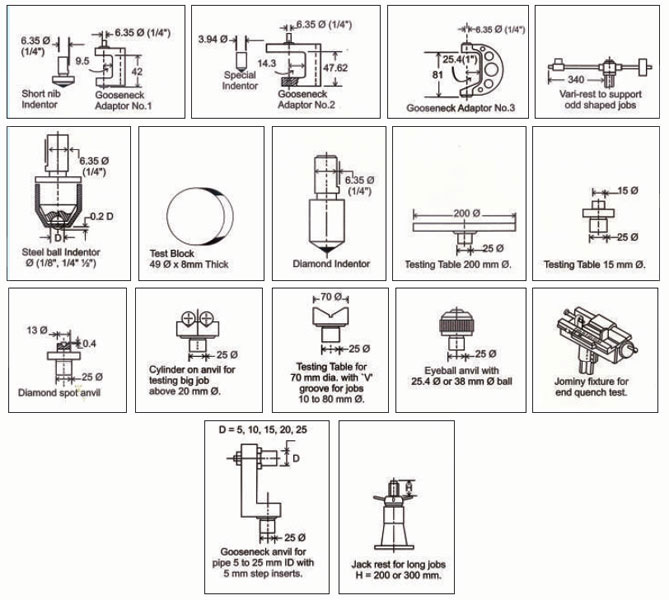

Standard Accessories :

Model |

RAS /RASM |

RAB-1 / RAB-250 |

TWIN |

Testing table 50mm dia |

1 pc. |

1 pc. |

1 pc. |

Testing Table 38mm dia with 'V groove for round jobs 6 to 45mm dia. |

1 pc. |

1 pc. |

1 pc. |

Diamond Indentor 120° |

1 pc. |

1 pc. |

1pc. |

Stell ball Indentor 1/16" |

1 pc. |

1 pc. |

1 pc. |

Test Block Rockwell 'C |

1 pc. |

1 pc. |

1 pc. |

Test Block Rockwell 'B' |

1 pc. |

1 pc. |

1 pc. |

Test Block Rockwell Superficial 'N' |

Nil |

Nil |

1 pc. |

Allen Spanners |

5 pcs |

5 pcs |

5 pcs |

Clamping Device |

1 pc. |

1 pc. |

1 pc. |

Dash Pot Oil |

1 Bottle |

1 Bottle |

1 Bottle |

Rubber bellow for elevating screw protection |

1 pc. |

1 pc. |

1pc. |

Instruction Manual |

1 Book |

1 Book |

1 Book |

Brinell Microscope |

Nil |

1 pc. |

Nil |

Stell Ball Indentor 2.5mm |

Nil |

1 pc. |

Nil |

Test Block HB 2.5/187.5 |

Nil |

1 pc. |

Nil |

Stell Ball Indentor 5mm ' |

Nil |

1 'pc. -. |

Nil |

Technical Data :

Model |

Unit |

RAS |

RASM |

RAB-1 |

RAB-250 |

TWIN |

Loads |

kgf. |

60, 100 150 |

60, 100 150 |

60, 100, 150, 187.5, 250 |

60, 100, 150, 187.5, 250 |

15, 30, 45 (Rockwell Superficial) 60,100,150 (Rockwell) |

Initial Load |

kgf. |

10 |

10 |

10 |

10 |

3 (Rockwell Superficial) 10 (Rockwell) |

Max. Test Height |

mm. |

230 |

230 |

230 |

330 |

330 |

Depth of Throat |

mm. |

133 |

133 |

133 |

150 |

150 |

Max. depth ot elevating screw below base |

mm. |

240 |

240 |

240 |

355 |

355 |

Size of base (approx.) |

mm |

170x430 |

170x430 |

170x430 |

210x474 |

210x474 |

Machine Height (approx.) |

mm |

655 |

655 |

655 |

850 |

850 |

Nett Weight (approx.) |

kg. |

65 |

65 |

65 |

100 |

100 |

Loads & Indentors for Hardness Testers for Rockwell & Brinell Tests.

Total load in kgf.

(Initial load 10 kgf.) |

60

|

100

|

150

|

187.5

|

250

|

Indentor

|

Diamond 120°

|

Ball 1/16" Ø

|

Diamond 120°

|

Ball 2.5 mm Ø

|

Ball 5mm

|

Test Scales

|

Rockwell A

|

Rockwell B

|

Rockwell C

|

Brinell,F/D2=30

|

Brinell, F/D2 =10

|

Suitable for

|

Tests on case hardened stell

|

Annealed, Ferrous & non ferrous metals

|

Annealed, hardened & tempered deep case hardened steel

|

Annealed steel & cast irons

|

Copper, Copper alloys & Al. alloys

|

Use of combinations of 60, 100 & 150 kgf. loads against Diamond Indentor and 1/16" stell ball indentor permit carrying out tests on Rockwell D, F & G scales. By use of 1/18", 1/4" & 1/2" dia. ball indentors in combinations of 60, 100 & 150kgf. loads, tests can be carried out on Rockwell E, H, K, L, M, P, R, S & V scales also.

Due to constant R & D, specifications and features are subject to change without notice. The diamension given are approximate.