- Loading accuracy as high as + 1% Servo controlled Motorized Valve incorporating of control modes - Standard manual control, Potentiometric control, Load rate control, Elongation rate control, Load hold mode, Auto start & initial valve open start.

- Straining at variable speeds to suit a wide range of materials. Printer & PC graphs enable study the behaviour of the material.

- Motor driven threaded columns for quick effortless adjustment of Lower cross-head-to facilitate rapid fixing of test specimen.

- Simplicity in reading because of digital readouts.

- Wide range of standard and special accessories.

- Easy change from plain to threaded and screwed specimens.

- Large effective clearance between columns enables testing of standards specimens as well as structures.

- Simple controls for ease of operation.

- Robust straining frame of an extremely rigid construction.

- Safe operation ensured by means of safety devices.

- Fully enclosed and protected pressure transducer.

- RS 232 serial port for PC control of Machine.

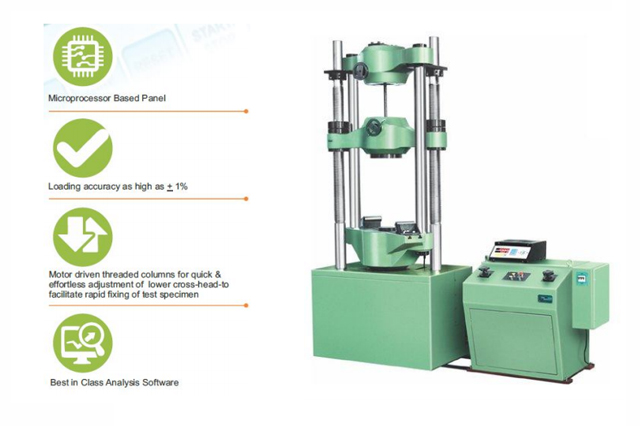

- Load Capacity: 100 kN, 200 kN, 400 kN, 600 kN & 1000 kN.

We are Supplier, Services Provider of Servo Controlled Electronic Universal Testing Machines and our set up is in Pune, Maharashtra, India

Application :

Electronic Universal Testing Machine is designed for testing Ferrous & Non-Ferrous materials under tension,

compression bending, transverse and shear loads. Hardness test on metals can also conducted.

Machine Consists of –

Straining unit :

This consists of a cylinder motor with chain and sprocket drive and a table coupled with the ram of the hydraulic

cylinder, mounted on to a robust base.

The cylinder and the ram are individually lapped to eliminate friction. The upper cross-head is rigidly fixed to the table by two strengthened columns.

The lower cross-head is connected to two screwed columns which are driven by a motor. Axial loading of t he

ram is ensured by relieving the cylinder and ram of any possible side loading by the provision of ball seating.

A Rotary Encoder of minimum resolution of 0.01mm is provided to measure the deformation of the specimen.

Tension test is conducted by gripping the test specimen between the upper and lower cross-heads.

Compression, transverse, bending, shear and hardness tests are conducted between the lower cross-head and

the table.

The lower cross-head can be raised or lowered rapidly by operating the screwed columns, thus facilitating ease of

fixing of the test specimen.

Control Panel:

The Control Panel consists of a power pack complete with drive motor and an oil tank, control valves and

electronic display unit.

Power Pack:

The power pack generates the maximum pressure of 200 kgf/cm2. The hydraulic pump provides continuously

non-pulsating oil flow. Hence the load application is very smooth.

Hydraulic Controls:

Hand operated release valve & motorized control valve are used to control the flow to and from the hydraulic

cylinder.The regulation of the oil flow is infinitely variable. Incorporated in the hydraulic system is a regulating valve, which maintains a practically constant rate of piston movement.

Control by this valve allows extensometer reading to be taken.

Principle of Operation for - Model: UTES

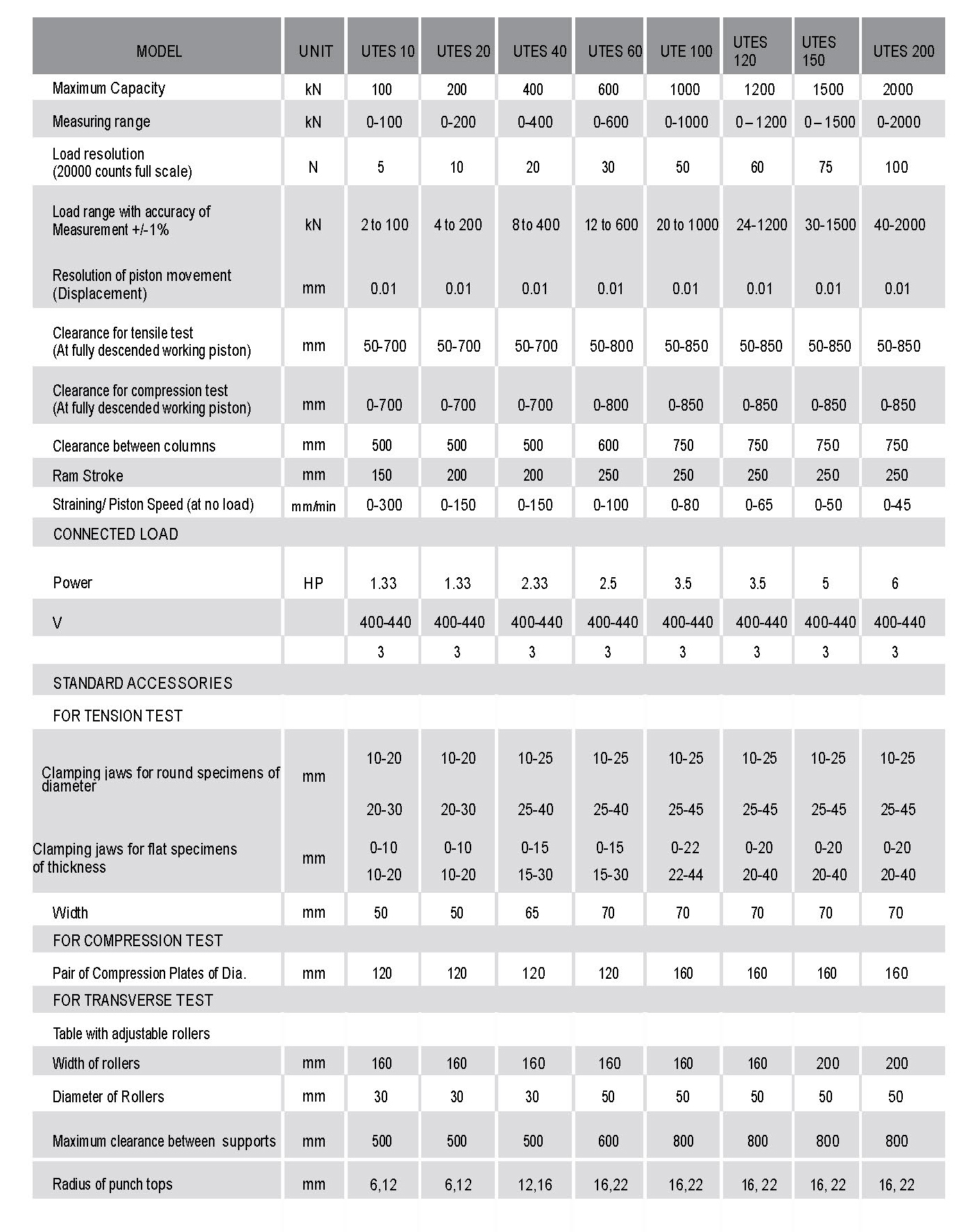

UTM right control valve is Servo Controlled in close loop mode as per mode selection. Following control modes available :

1) Standard Manual control

2) Potentiometric control

3) Load rate control

4) Elongation rate control

5) Load hold mode

Also Auto start, Potentiometric start &initial value open start options are available for test start to take care of slippage & different specimen types. Load is applied by a hydrostatically lubricated ram.

Main cylinder pressure is transmitted to the pressure transducer housed in the control panel.

The transducer gives the signal to the electronic display unit, corresponding to the load exerted by the main ram.

Simultaneously the encoder fitted on the straining unit gives the mechanical displacement.

Electronic Control Panel:

- In electronic panel 8085 microprocessor is used for basic UTM operation & an 8 bit dedicated micro controller is used for close loop & Servo control.

- Panel is having parallel printer port.

- RS 232 C serial port for PC interfaces.

- 2 lines x 8 digits 7 segment display & membrane keyboard for data entry.

- 20 data sets and 50 results storage.

Accuracy and Calibration:

Electronic Universal testing machine is closely controlled for sensitivity, accuracy and calibration during every stage of manufacture.

Machine is calibrated over each of its measuring range in accordance with the procedure laid down in British standards1610: Part1: 1992 and IS 1828: Part1: 1991.

Electronic Universal Testing Machine complies with Grade “A” of BS: 1610:Part1:1992 and class 1 of IS-1828-Part1:1991.

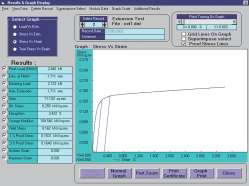

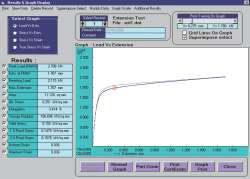

Software Package - Tension & Compression test Software package for Model: UTES

Input Data

Wide range of Control Modes with Input Data entry.

Load Vs Extension

Displays graph for extensometer readings against load with proof lines for proof stress.

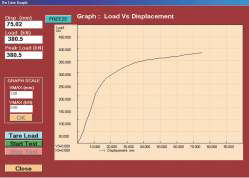

Real Time Graph

Real time values of load & displacement/extension used for plotting its graph & can be seen real time during testing.

Statistics

Batch test reports with statistics for batch sample results.

Graph Superimpose with Point Tracing

Graph comparison, superimpose of batch sample tests with point tracing facility.

Windows based software available for -

Online graph on PC, Data analysis, Statistics,

Point tracing, superimposing graphs to compare

with standard, zooming graph etc.