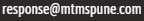

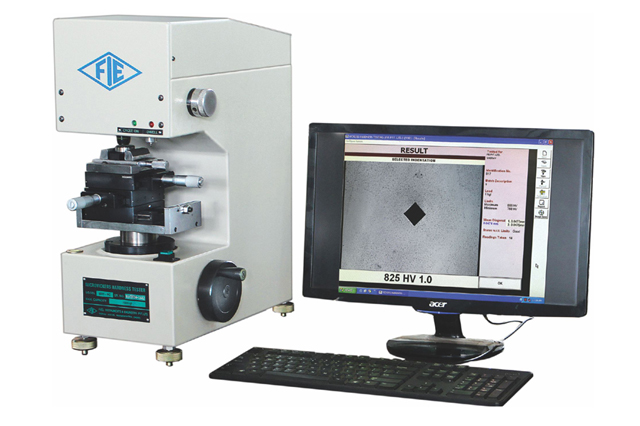

Computerised Micro-Vickers Hardness Testers (Models : MV-1 PC)

Construction :

The machine frame is designed to accommodate the high precision loading system. Specimen is clamped by vice or supported by proper fixtures. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of dead weights. After a lapse of time, the load is removed automatically. The image id digitallized using a CCD Camera fitted on the machine and is captured by the PC. The diagonals of the indentation are measured by the PC and the Micro Hardness number is displayed directly on monitor.

Scope of Supply

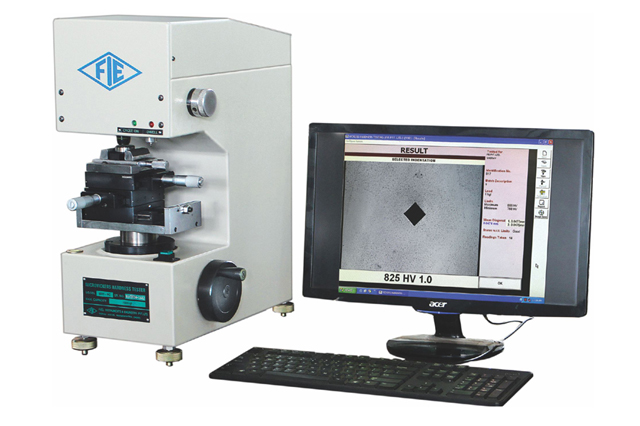

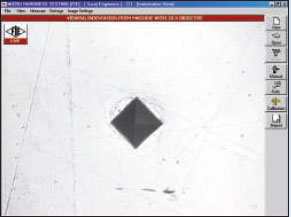

Indentation View

Indentation View

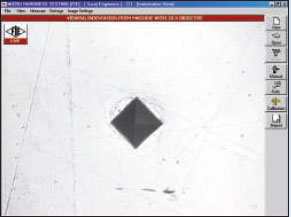

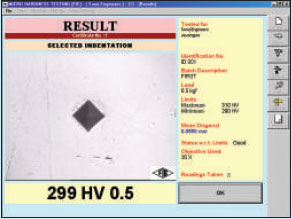

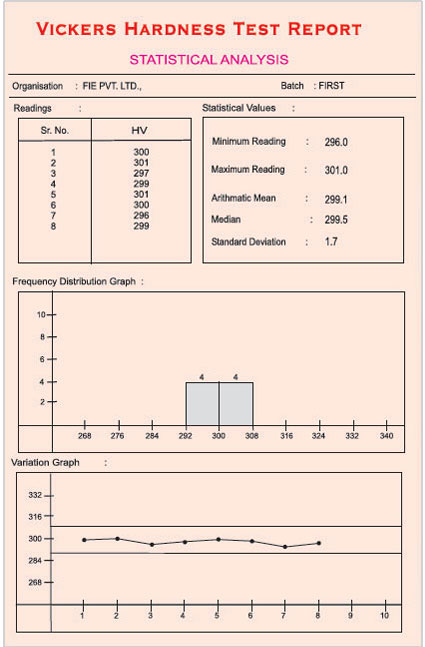

Result View

Result View

• PC & Printer is not in our standard scope of supply.

We are Supplier, Services Provider of Computerised Micro-Vickers Hardness Testers, Portable Hardness Testers and our set up is in Pune, Maharashtra, India. We provide our whole range to ALL OVER INDIA, but; We majorly target customers from Gujrat, Ahmedabad, Surat, Rajkot, Vadodara, Anjar, Vapi, Kutch, Bhuj, Karnataka, Bengaluru, Hubballi, Dharwad, Belgaum, Maharashtra

Computerised Microvickers Hardness Tester is a simple and accurate means to produce and automatically measure the diamond indentation to give micro hardness numbers directly. These testers are suitable for measuring the hardness of precision metallic parts with wide testing range - from soft to hard, and their accurate results are widely acclaimed. These testers strictly conform to IS:1754:2002 and ISO 6507-2:1997.Construction :

The machine frame is designed to accommodate the high precision loading system. Specimen is clamped by vice or supported by proper fixtures. The test cycle is fully automatic. The accurate load is applied on a diamond indentor by means of dead weights. After a lapse of time, the load is removed automatically. The image id digitallized using a CCD Camera fitted on the machine and is captured by the PC. The diagonals of the indentation are measured by the PC and the Micro Hardness number is displayed directly on monitor.

Features :

- Fully Computerised (PC based) Micro Hardness Tester.

- Direct and accurate measurement of micro hardness number using "State of the art" image processing technology.

- Wide testing range : From soft metal such as lead up to hardest, like hardened steel.

- High accuracy and repeatability of measurement at all loads.

- Small size of indentation makes it a non destructive testing on finised components.

- Load slection by external knob.

- Motorised loading and unloading cycle.

- Small loads allow testing of thin sheet metals.

Advanced Window 98 Based Software :

- Latest GUI features with user friendly software.

- On line indentation setting and focusing on PC monitor.

- Advanced Image Processing : Algorithms implemented for precise calculations of hardness numbers with various options to cover all ranges of specimens.

- Batch File Processing : Option for data/ storage and reports generation for case depth analysis etc.

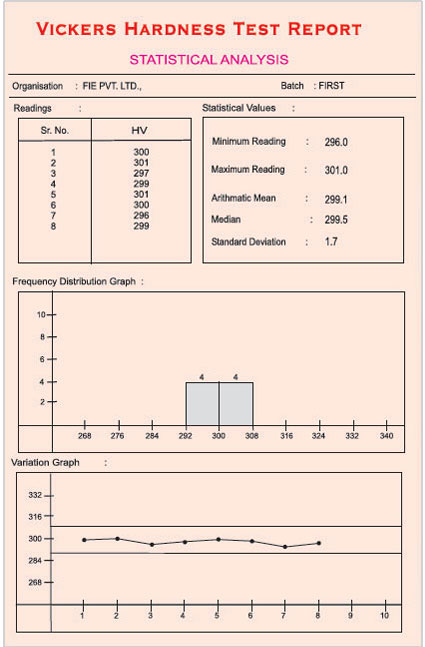

- Statistical Evaluation : Software for calculating standard deviation, mean, medium, frequency distribution graph, variation graph etc.

- Calibration mode facility.

Scope of Supply

- Basic machine with CCD Camera, optics with illumination system and connecting cable.

- PCI video capture card with driver software.

- PC and Windows operating system is procured by customer. Minimum Pentium II with 64mb RAM & Window 98 / 98SE operating sytem required.

Indentation View

Indentation View Result View

Result ViewTechnical Data : |

||

Test Loads |

: |

10, 20, 50, 100, 200, 300, 500 gf |

Maximum Test Height |

: |

30 mm with clamping vice 50 mm without clamping vice |

Sample Stage (XY stage) with micrometer heads of 0.01 LC |

: |

10mm movement in each axis |

Clamping vice capacity |

: |

40mm max. |

Scale least count |

: |

0.0001 mm |

Machine dimension |

: |

L 450 X W 275 X H 535 mm (Aprox) |

Weight (approx.) |

: |

48 kgs |

Measuring Range |

: |

0.01 to 0.2 mm |

Standard Accessories : |

||

Vickers Diamond Indentor 136 pyramid |

: |

1 No. |

Standard Test Block |

: |

1 No. |

Spanners |

: |

1 Set |

Supply Cord |

: |

1 No. |

PC interface cable |

: |

1 No. |

Video Capture Card |

: |

1 No. |

Microvicksys Software CD |

: |

1 No. |

Instruction Manual |

: |

1 No. |

• PC & Printer is not in our standard scope of supply.