We are Supplier, Services Provider of Auto Correction Vertical Balancing Machines and our set up is in Pune, Maharashtra, India

Technical DescriptionMachine Model Balance Tech VAC are vertical type single plane hard bearing balancing machine provided with -

- DSP based measuring panel

- Servo Drill head for correction

- Ideal for disc shaped rotors such as clutch plates, flywheels, fan blades, Magnetos, Grinding wheels, impellers etc.

Operation Cycle :

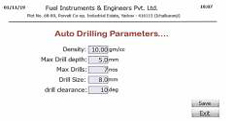

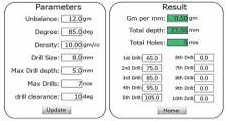

The working cycle is fully automatic with unbalance indication while rotor running and after stopping the balancing cycle it precisely rotates to its correction position, further Vertical drill head cycle starts for correction and asks for following parameters -

- Material Density

- Drill Size

- Maximum drill depth

- Allowed no. of holes

- Center distance between two hole.

Standard Features of control panel

- DSP controller based processing

- Digital display for unbalance indication

- Digital display for RPM Indication

- Auto - Stop

- Simultaneous indication

- On screen keyboard

- Tolerance indicators

- Data Storage

Auto Correction Vertical Balancing Machines with Touch Screen Based Measuring Panel

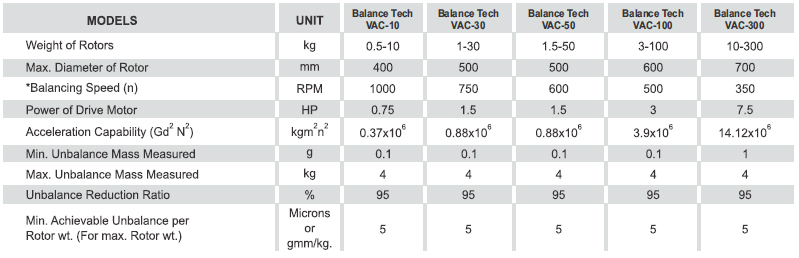

Hard Bearing Models : BALANCE TECH VAC

Operation Cycle

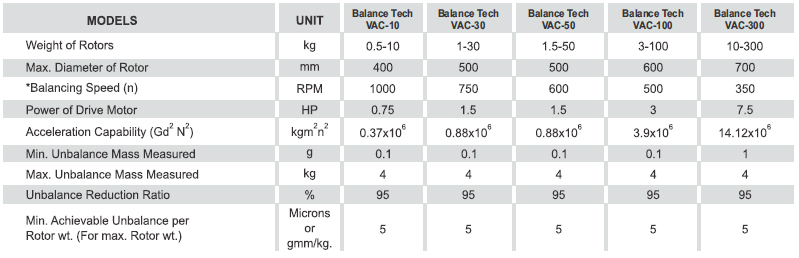

Technical Specifications :

- The balancing speed depends upon selection of the rotor diameter, where drive is to be given and the motor pulley diameter.

- All the machines above operate on mains supply of 400 to 440 V, 3Ø, 50 Hz.

- Due to constant R&D, specifications and features are subject to change without notice. The dimensions given above are approximate.

- PC & Printer is not in our standard scope of supply.